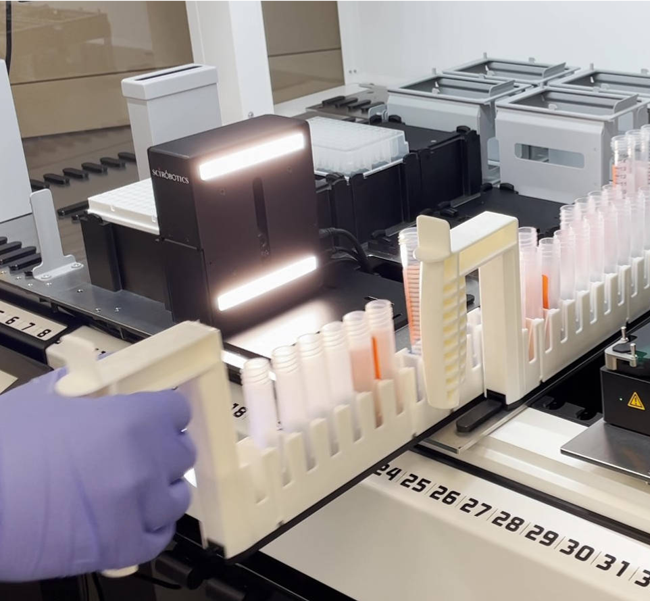

Save time and scan hundreds of tubes easily and reliably

Any tube rack / runner can be used with Rack2D and Rack2D is compatible with any liquid handler

Integrated software gives constant feedback via sound and on the screen

Read DataMatrix, QRCode, Code128, Interleaved2of5 and all other major barcode types

Tube barcodes can be filtered by barcode type, length or a regular expression

Any tube rack / runner can be used with Rack2D. It must provide a clear view of the tube barcode and physical space to place the special positional barcodes (PosCodes).

PosCodes are included with Rack2D and are applied to the tube rack.

Rack2D uses PosCodes to determine the position of the tube in the tube rack and assigns tube barcode to the correct tube.

In addition to Rack2D customized runner labeling, it inherently compatible with Tecan’s Fluent-ID runners labeling.

The Rack2D device can be set to scan either left side or right side labels.

Rack2D continuously measures the distance to the loaded tube rack and will prevent scanning of tubes if tube rack is being loaded in the wrong grid

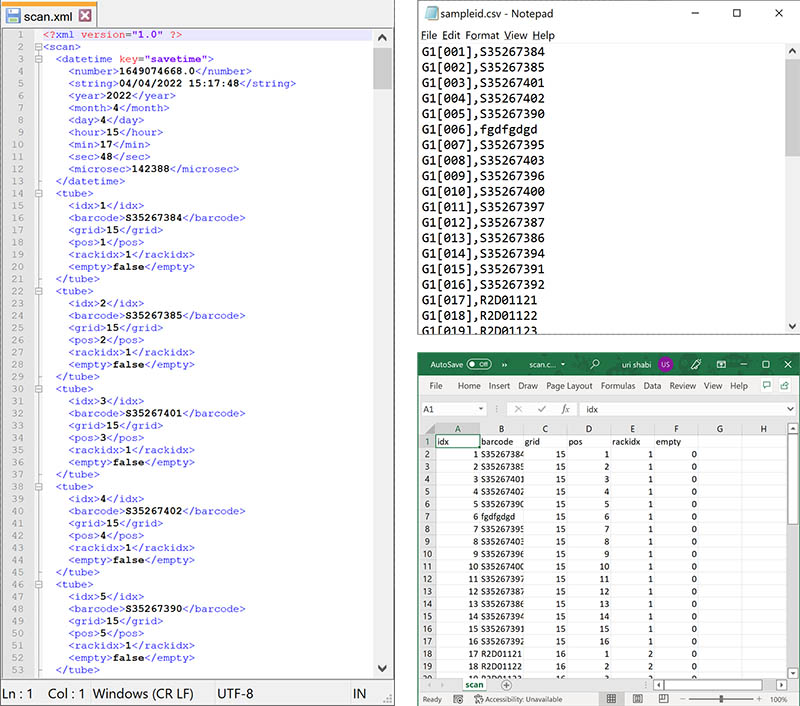

Rack2D supports different output types including CSV, XML and flexible text formats.

Tube barcodes can feed into sample tracking software or used by any LIS.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_QVKZWMCZ98 | 2 years | This cookie is installed by Google Analytics. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |